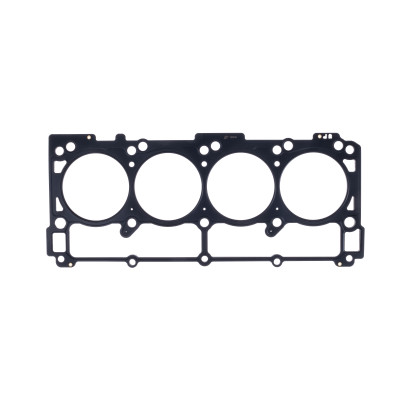

Unique Multi-Layered steel head gasket embossment formation process optimizes the embossment radius, reduces stress points, enhances gasket conformability, and provides uniform clamp load distribution. This all results in superior surface contact between block and cylinder head. All head gasket layers go through an additional process to significantly reduce forming induced stress. Advantages are reduced brittleness in material, increased flexibility and deformation retention. This stabilizes the gasket, resulting in reduced cylinder bore distortion and improved combustion seal for the extreme cylinder pressures found in high compression, supercharged and turbocharged applications. A proprietary polymer coating ensures the micro-seal of engine coolant and oil fluids.

A typical MLS head gasket requires a smoother (30Ra) surface finish than composite head gaskets. Mr. Gasket's proprietary polymer coating will seal a surface finish twice as rough (60Ra) as a typical MLS head gasket. For high performance street, drag race and oval track use. Mr. Gasket provides a Limited Lifetime Warranty for MLS cylinder head gaskets.

A typical MLS head gasket requires a smoother (30Ra) surface finish than composite head gaskets. Mr. Gasket's proprietary polymer coating will seal a surface finish twice as rough (60Ra) as a typical MLS head gasket. For high performance street, drag race and oval track use. Mr. Gasket provides a Limited Lifetime Warranty for MLS cylinder head gaskets.

Features:

- Gasket bore - 4.100 inch; Compressed thickness - .040 inch

- Manufactured from 3-layer premium grade stainless steel and state of the art laser cutting

- Optimized sealing embossments seals extreme cylinder pressure

- Provides excellent stability and reduces cylinder bore distortion.

- Proprietary polymer coating ensures the micro seal of engine coolant and oil fluids.

- Ideal for supercharged, turbocharged, nitrous oxide and extreme compression ratio engines

- For high-performance street, drag race and oval track use